What I learned about craftsmanship, is that the simpler the design, the more difficult it is to make it good.

The simpler it is, the more it will stand out when it is not done right.

Groove lines

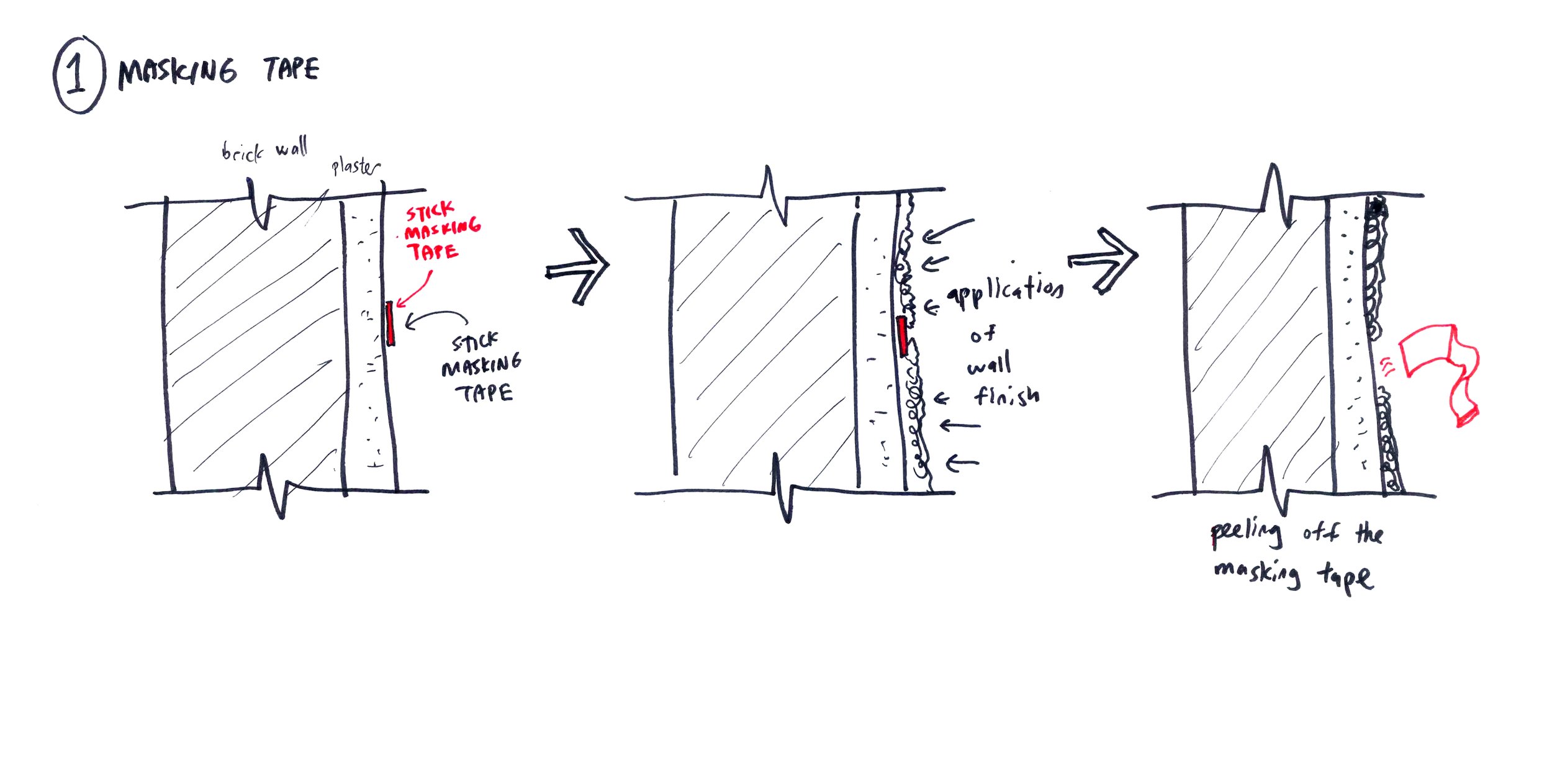

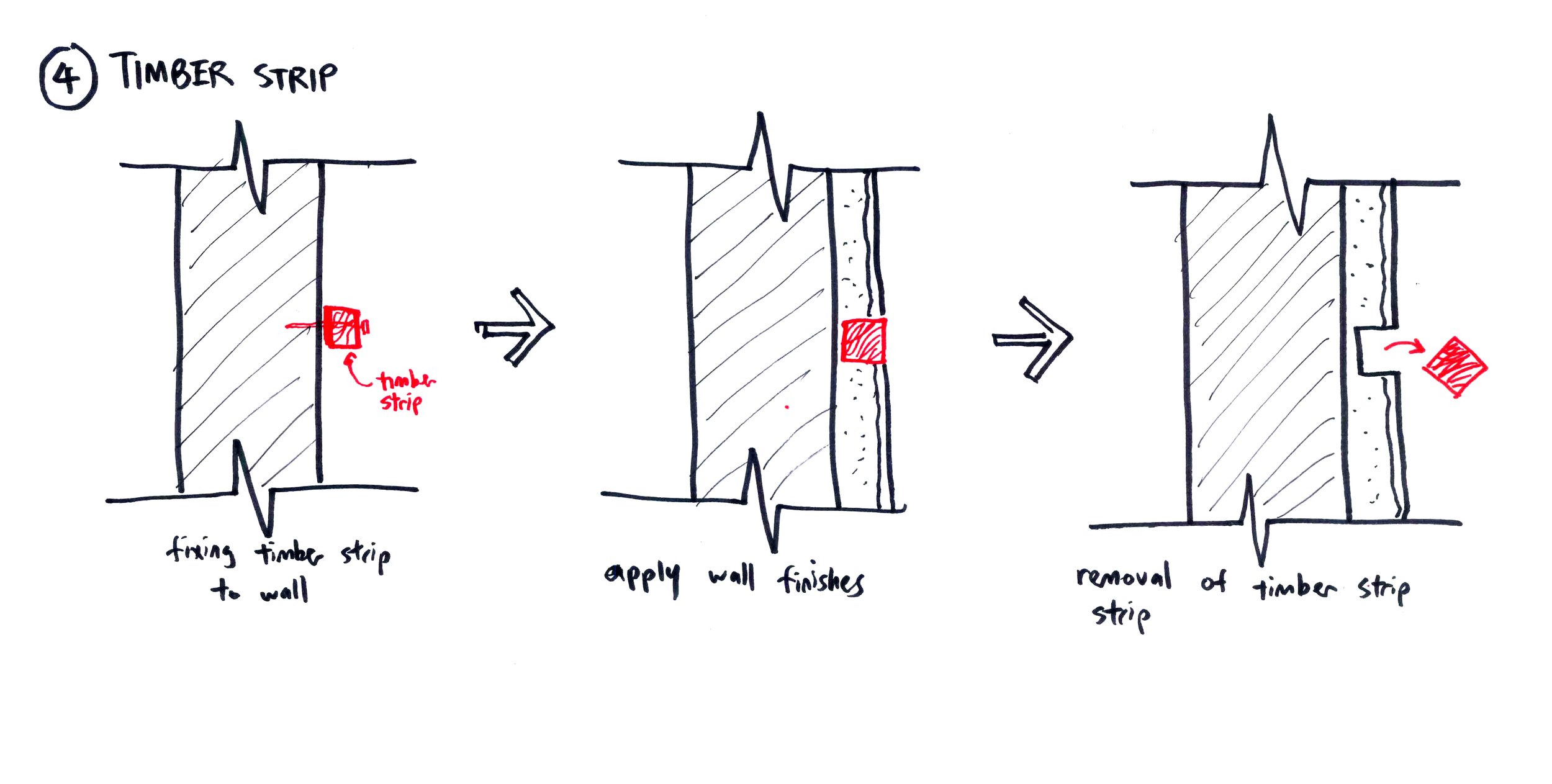

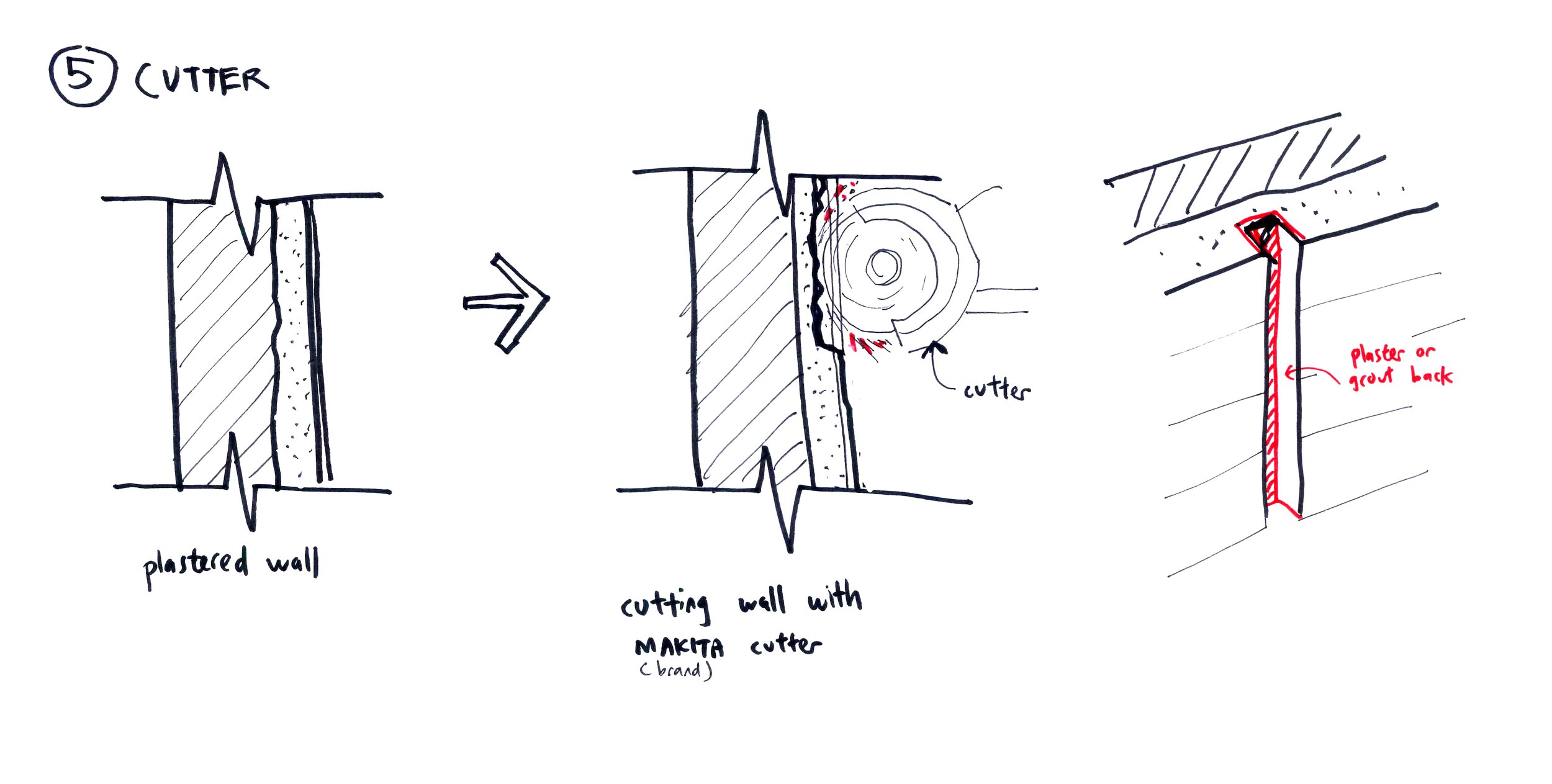

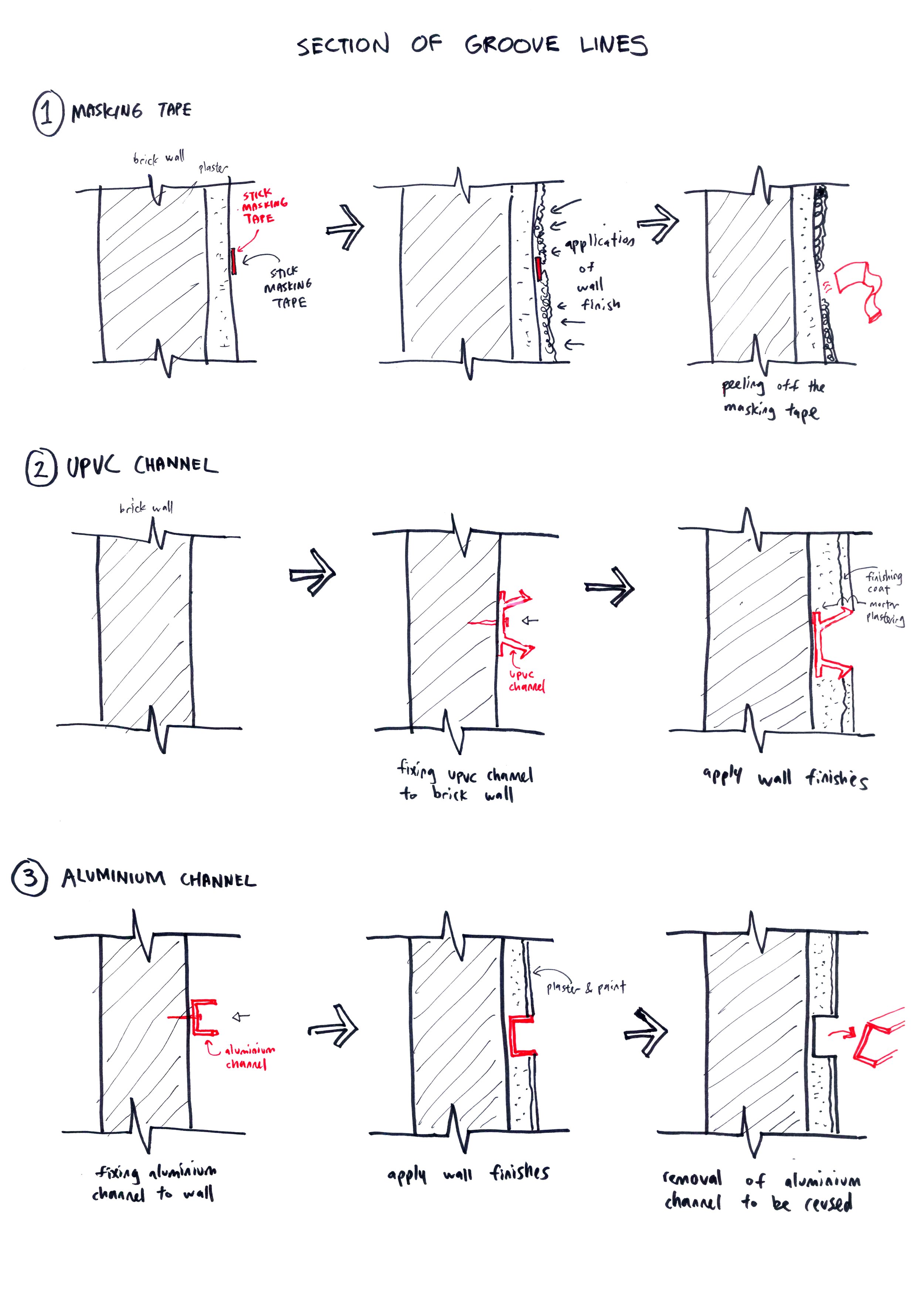

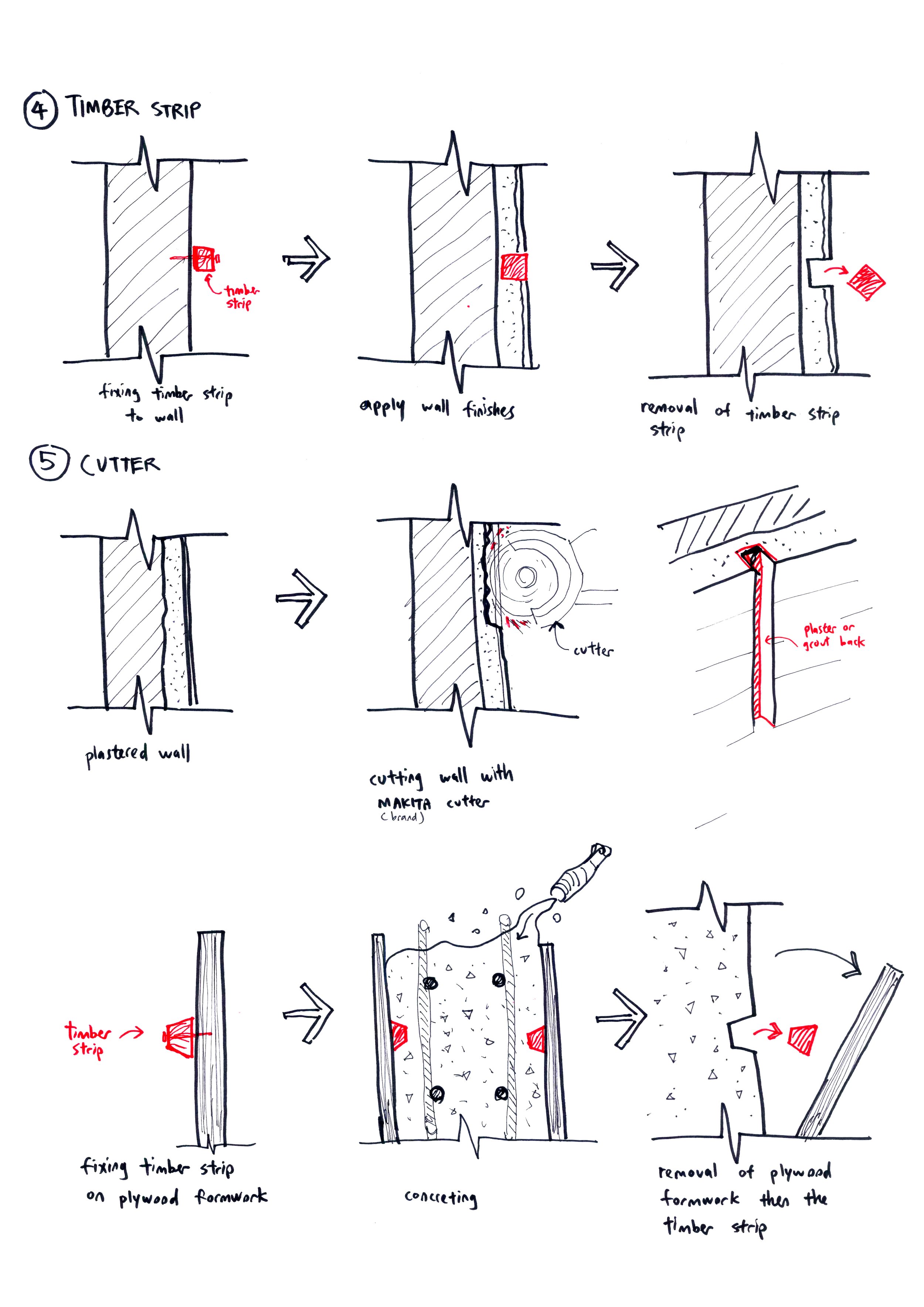

There are several ways to make a groove line on an architectural element. It could be by omission and addition of the actual groove line material. The actual groove line material itself may be left behind on the wall, or it may be the trait left behind by the material on the flat surface that becomes the groove line.

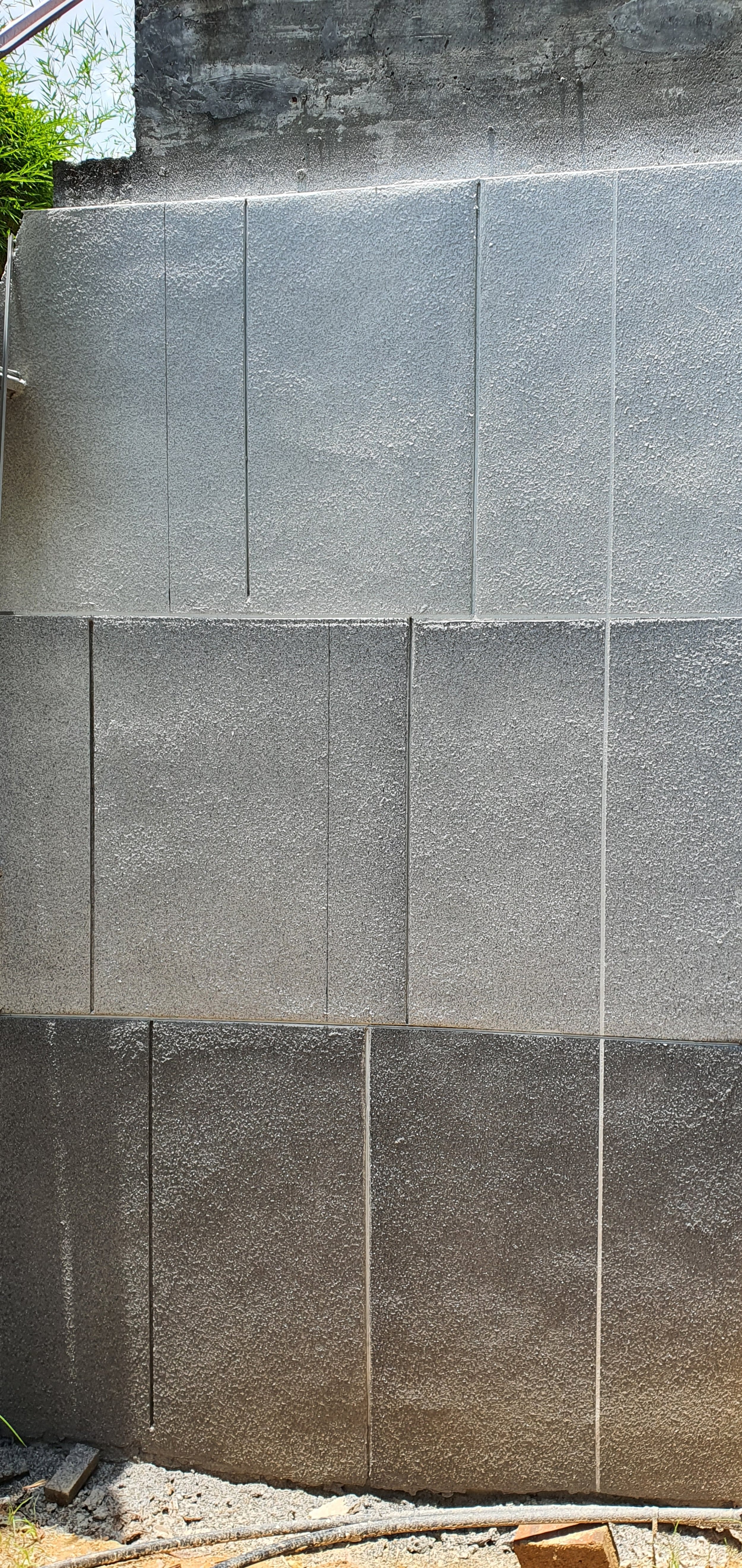

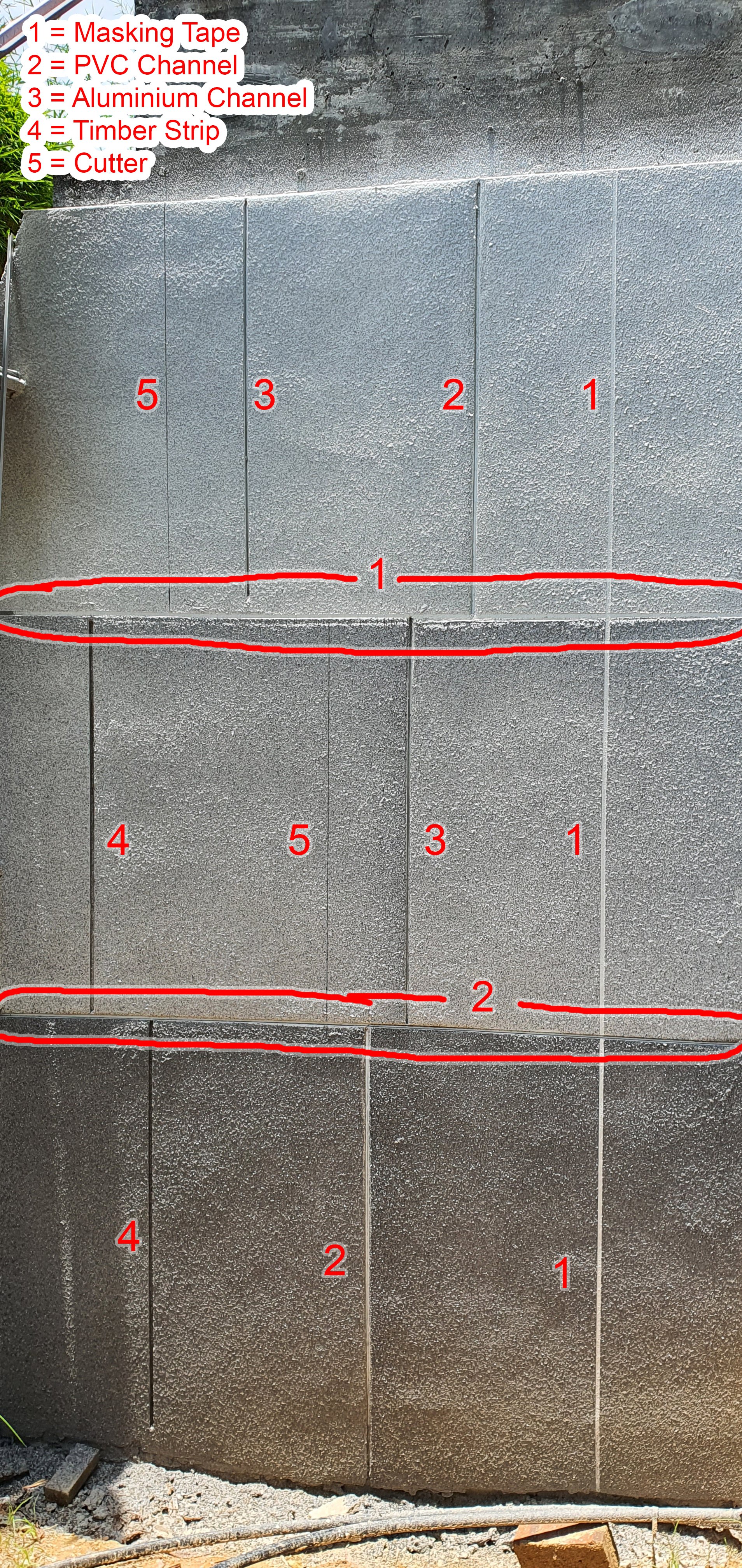

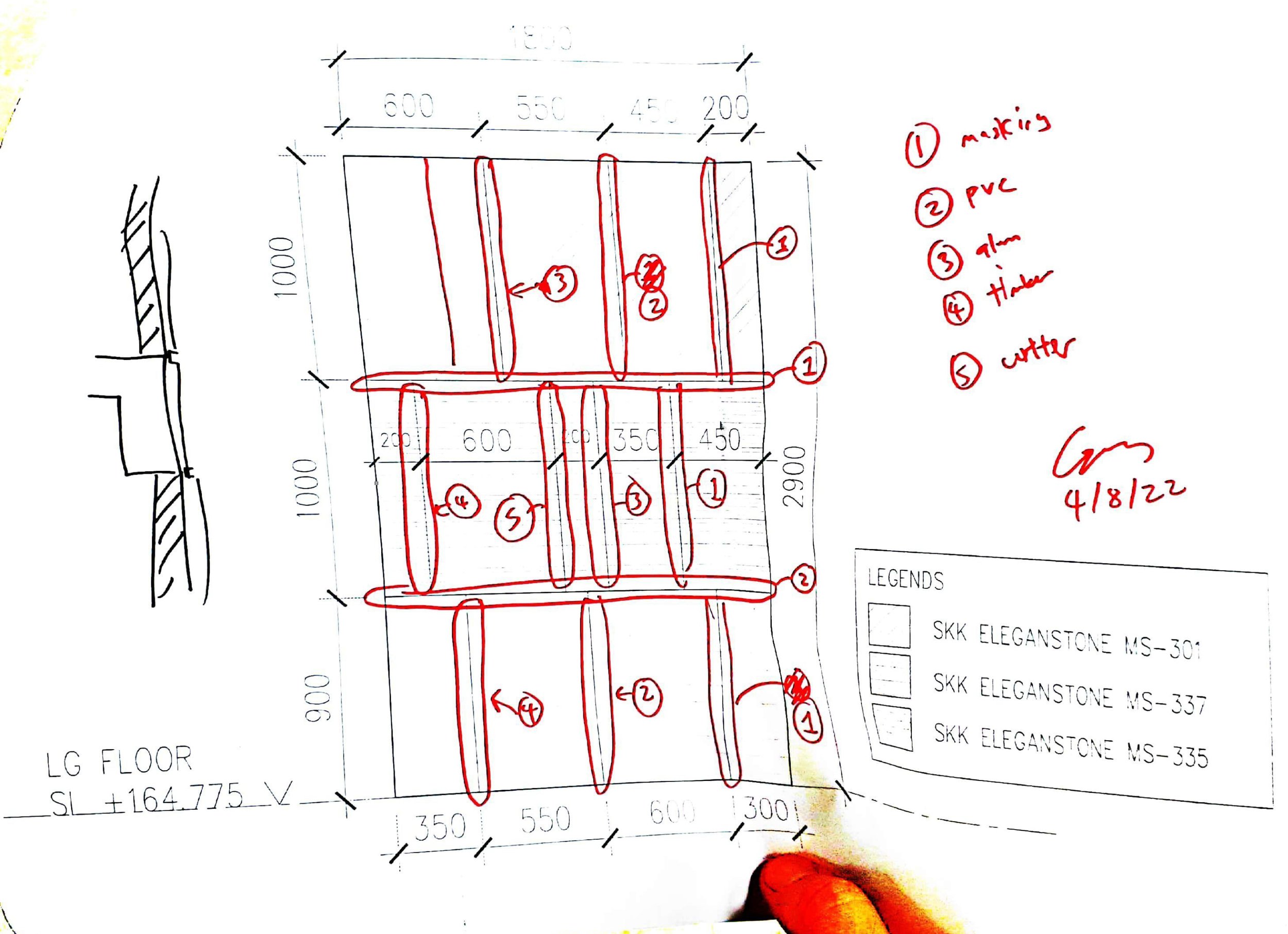

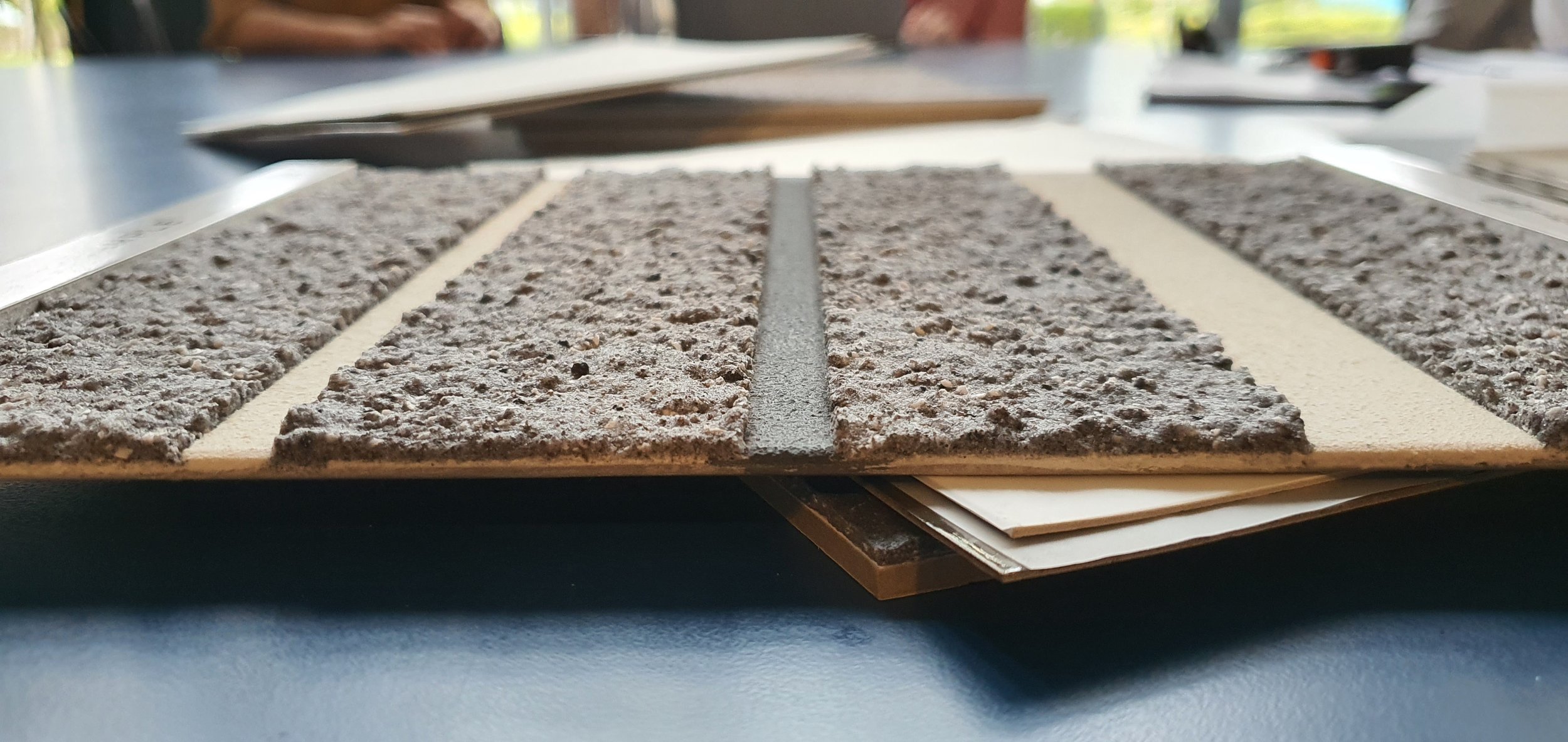

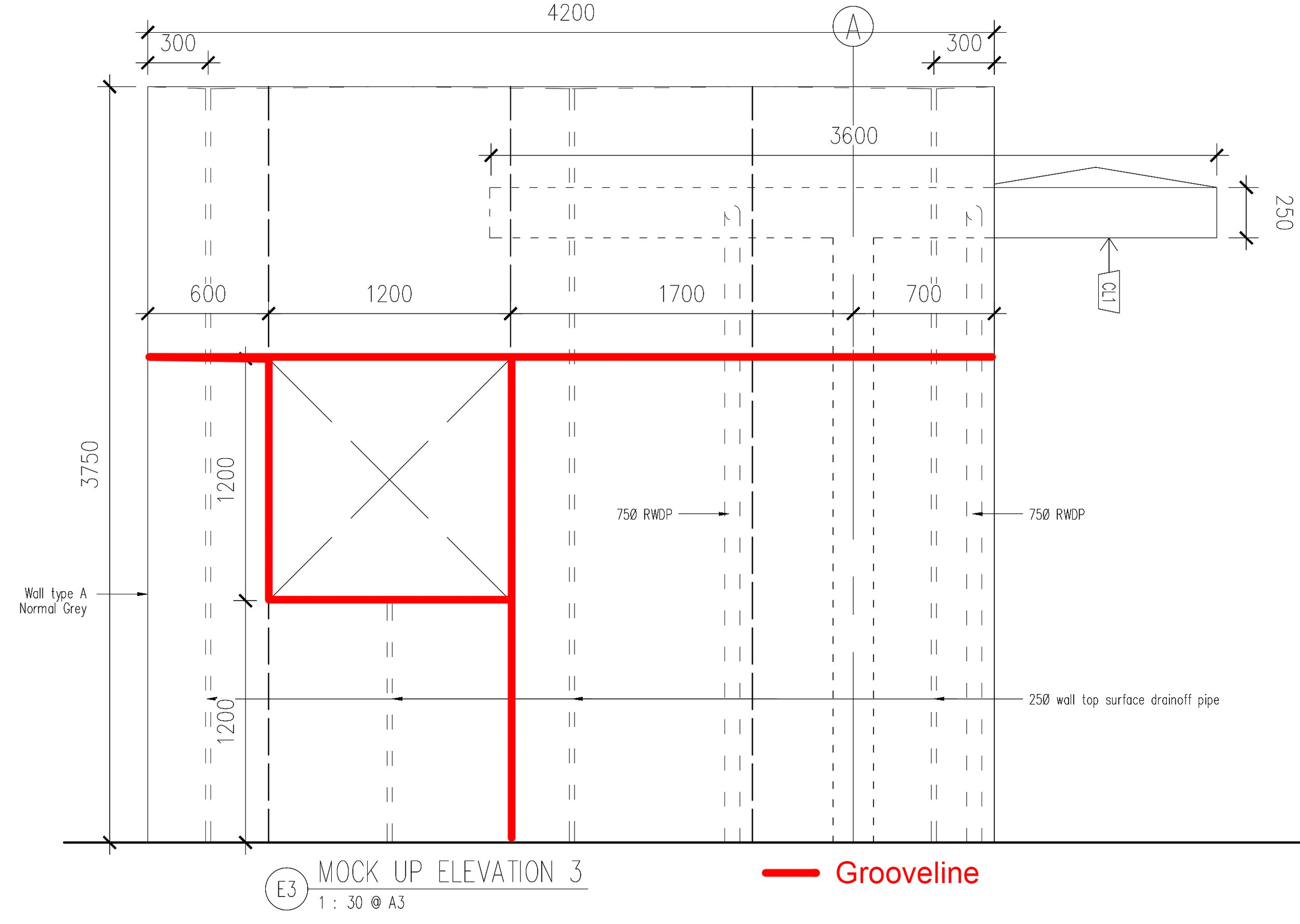

In the example below, we constructed a Mock-up with 5 types of groove lines, each with a different type of method or material.

This Mock-up is a collaboration between the Architect and the Main Contractor. What’s good about a design detail, or a design intention, if the contractor is unable to construct it well?

The five types of groove lines in this Mock-up are as follows:

A) Masking Tape

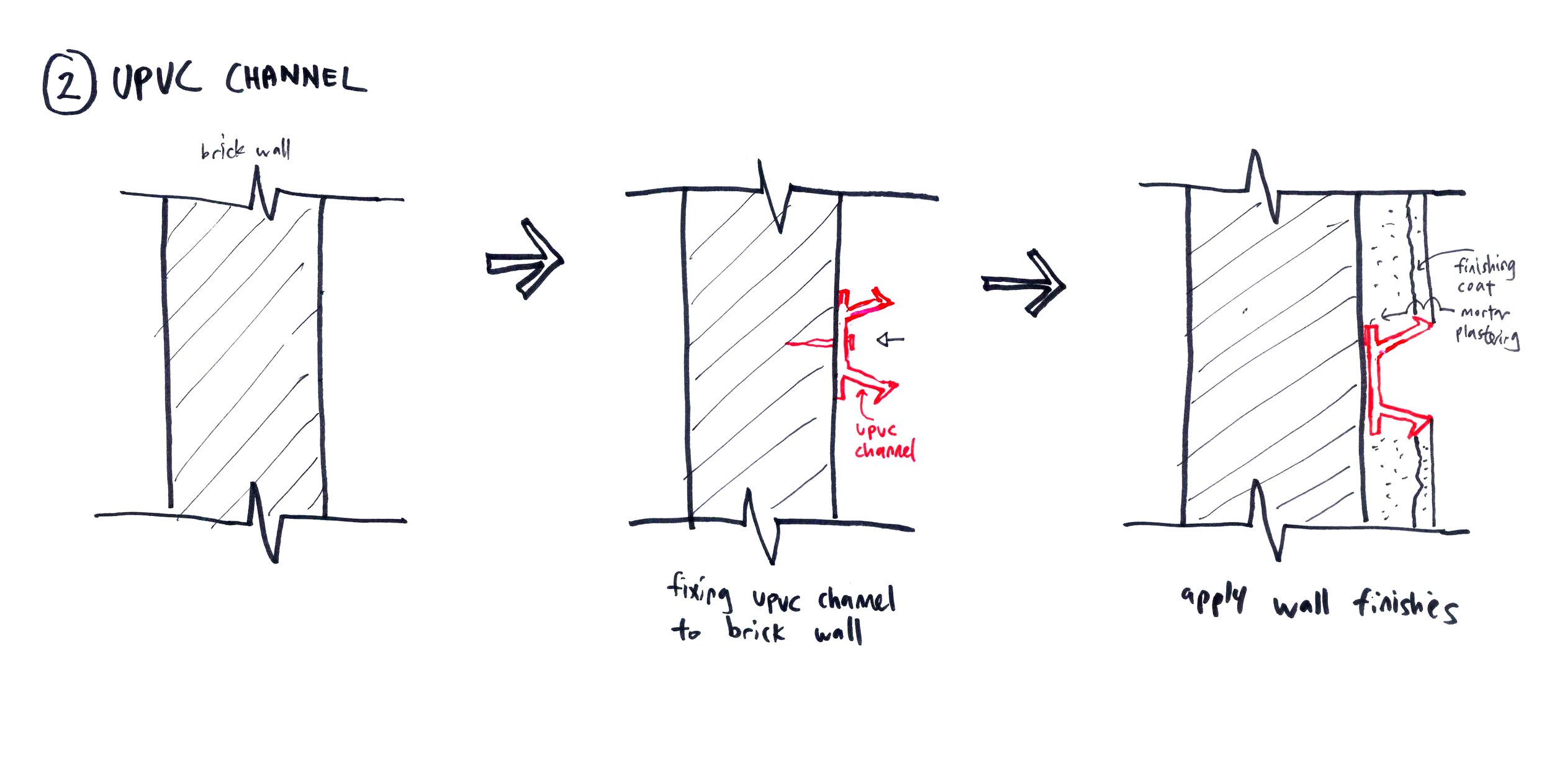

B) Selected UPVC Channel

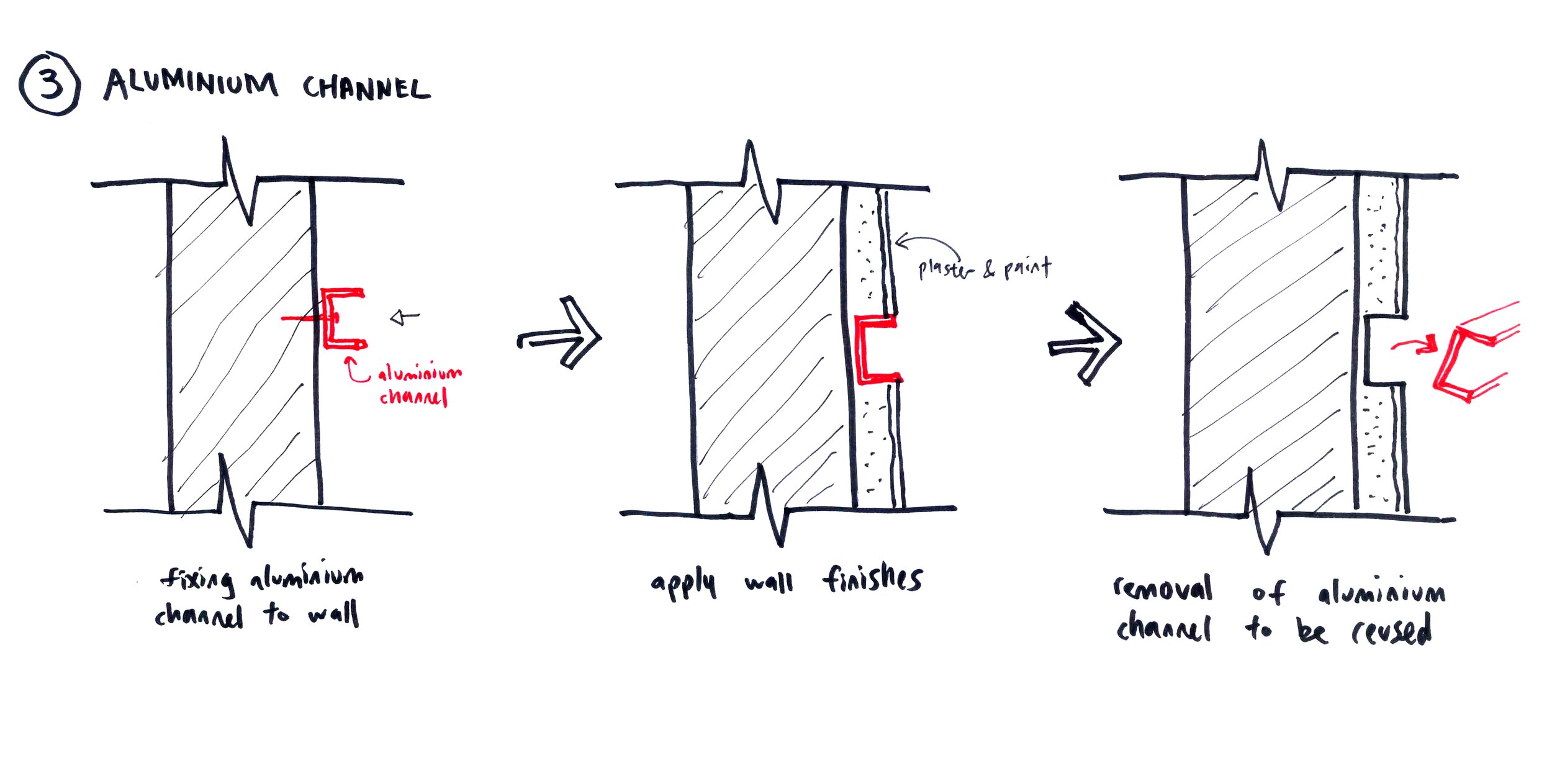

C) Aluminium strip

D) Timber Strip

E) Cutter

In this Mock-up, we assess the groove lines based on a few factors:

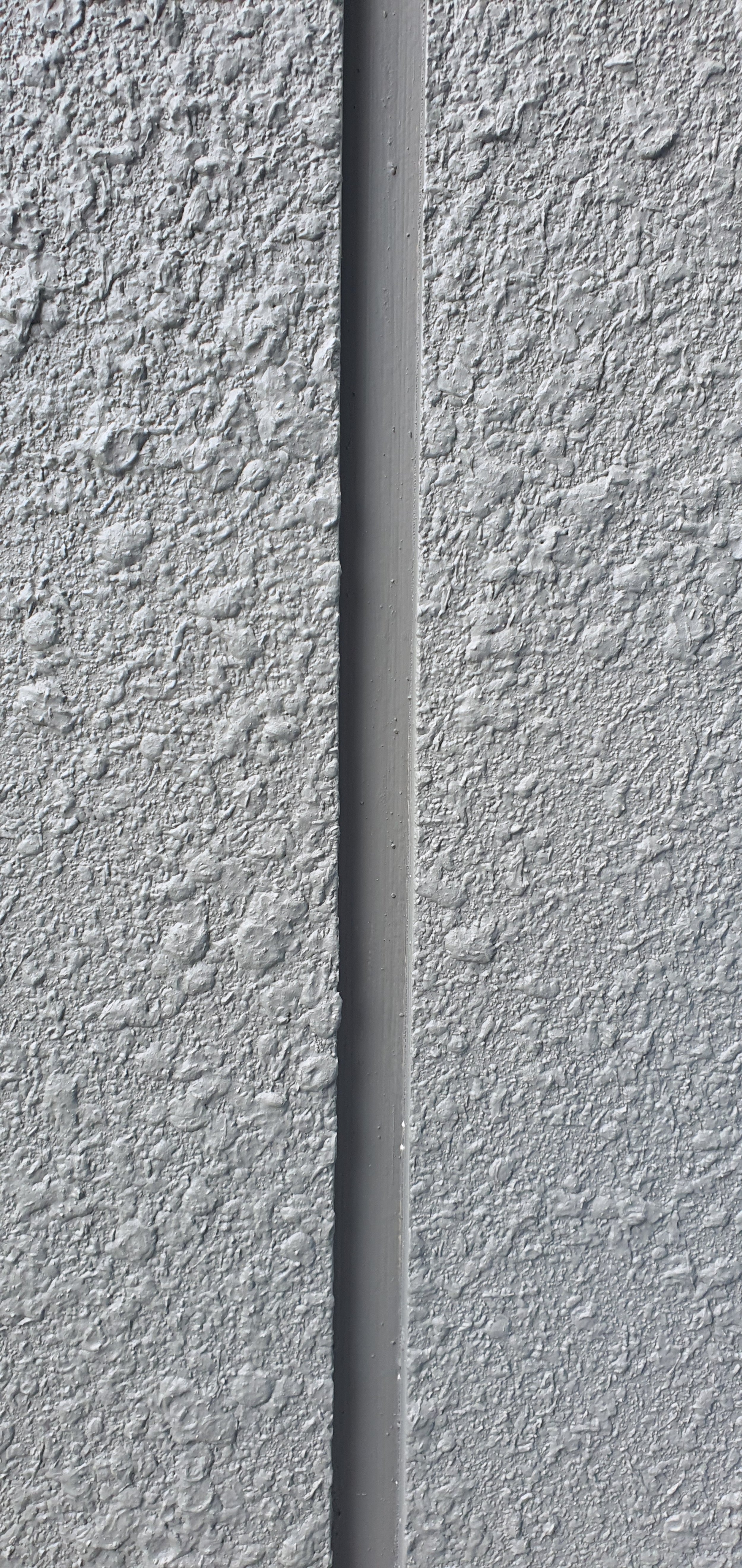

1) How straight is the groove line?

2) How is the groove line edging? Is the groove line neat?

3) How is the recess of the groove line? Is it nice?

4) How easy is the method of making the groove line?

5) How much time and cost are required for the groove line to be constructed?

6) When the groove line run straight over a long length, how likely would the groove line not be straight? Which method has the lowest room for error?

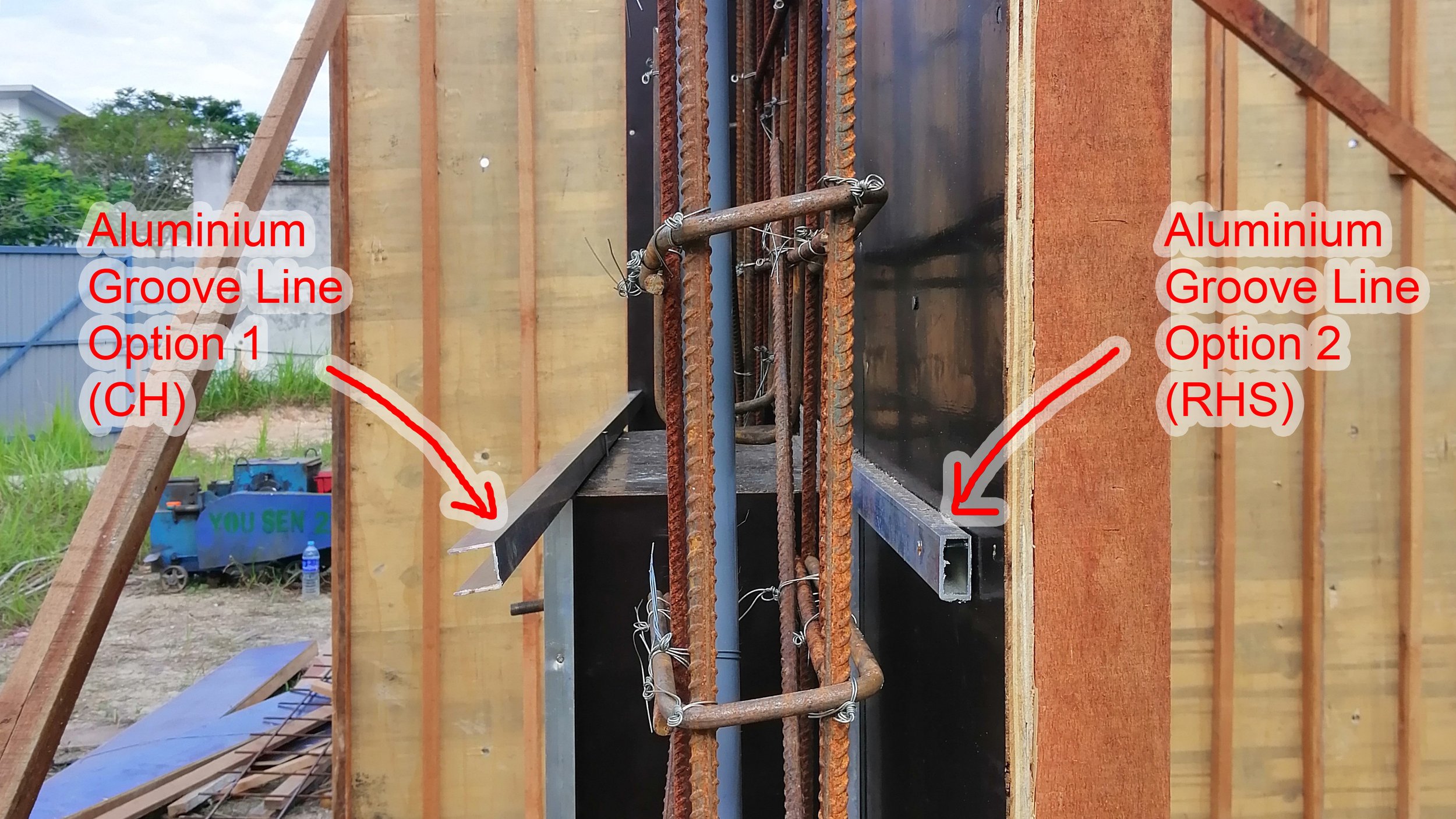

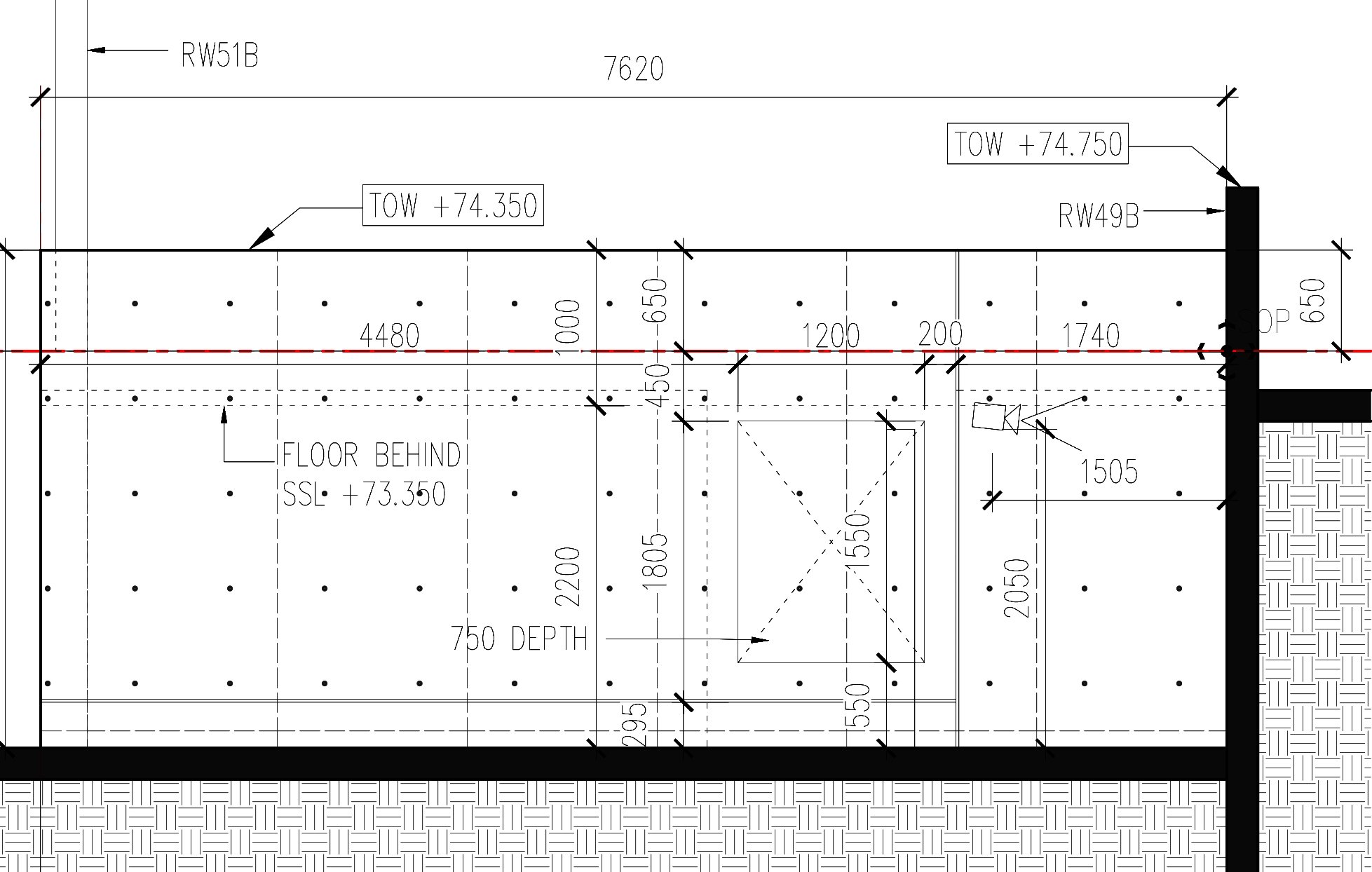

In another project consisting of multiple bare-faced reinforced concrete walls, one of the main design features is to have groove lines running around the walls.

The making of the wall groove lines in this project needs to be done differently. It is because the wall is constructed differently, in a totally different material. Besides, unlike brick walls, there is no opportunity to add any further finishes on top of the constructed concrete wall. Everything has to be precise and to be planned right at the beginning.

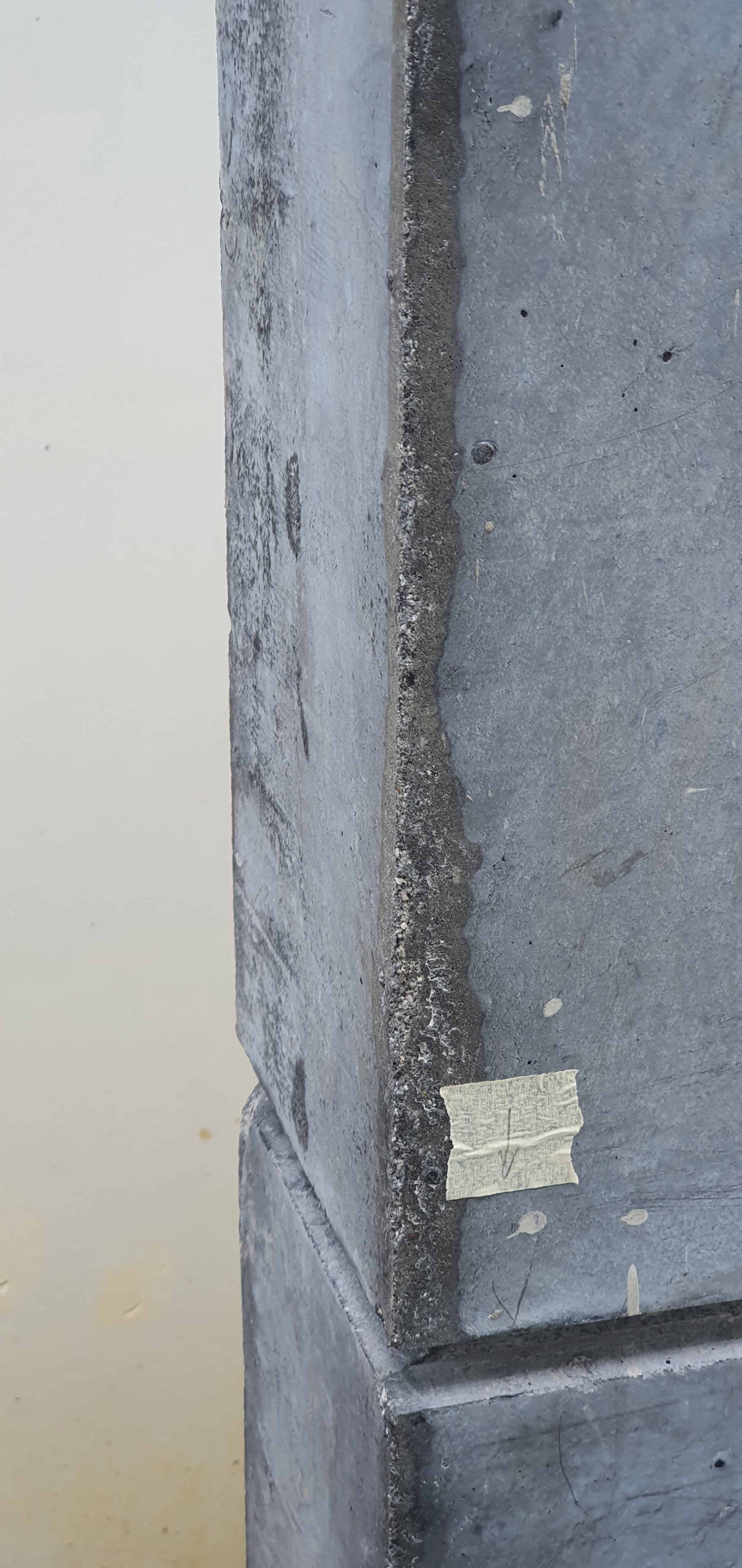

We discovered that the groove line edging is often damaged in the process of removing the aluminium profile away from the concrete wall. The damage is worst, especially in the area where there is concrete seepage into the gap between the aluminium strip, and the formwork.

Therefore, we scout and manage to find pre-made timber strips with slanted chamfer edging that we think is perfect for forming groove lines. The slanted edging allows much easier removal of the groove line material, thus reducing the chances of having damaged groove line edging.

Mistake?

Work done on any off-form bare-faced concrete walls is truthfully and entirely exposed, as there are no further finishes that could be applied to the wall to improve or amend the appearance. The craftsmanship and effort to make it right start from the very beginning.

As compared with brick walls with plaster and paint, the groove line with mistakes could be redone and amended until it is right, and the wall could be touched up until the whole wall is even and flat.

As an Architect, would you instruct to tear down the entire concrete wall, because of the mistakes and imperfections of the groove line? How much of this is a mistake, or a feature?

How much should an Architect care about the difficulty of the actual making of the design detail?